While the sun has forever been affiliated with solar power, so too has the aluminum frame. Some solar PV panels have gone frameless with cells sandwiched between two pieces of glass, and other more flexible designs use polymers to keep electrons protected. But for every other solar panel with a frame out there, chances are it is made of aluminum. For environmental and practical reasons, there’s now growing momentum to explore other framing material options.

Aluminum likely became the dominant material choice for panel frames back when the industry started because it is lightweight and has excellent corrosion protection.

“It was the safe bet 40 years ago, but it’s not the right choice for what is going to be huge growth in solar for the next 40 years,” said Gregg Patterson, CEO of steel frame startup Origami Solar. The company’s argument for switching to steel framing: aluminum is expensive and has a huge carbon footprint.

There are some facts to back this up. According to a July 2022 review of the global metals market, cold-rolled steel was averaging $0.93/lb while aluminum was holding near $2.45/lb. According to Risen Energy, which recently added a steel frame option to its popular Titan solar panel line, it takes 13.5 MWh of thermal power to produce one tonne of aluminum (equivalent to 11.2 tonnes of CO2), while it only takes 4.5 MWh to make one tonne of steel (1.8 tonnes of CO2). And with nearly all aluminum frames coming from China, a country that relies on coal-powered electricity, solar panel frames have a dirty energy origin.

“The aluminum frame is the most expensive component of a module after the solar cells,” Patterson said. “[With steel] you get cheaper, cleaner, higher performance and it can be domestically sourced. It hits virtually every aspect of what the industry is looking to do now.”

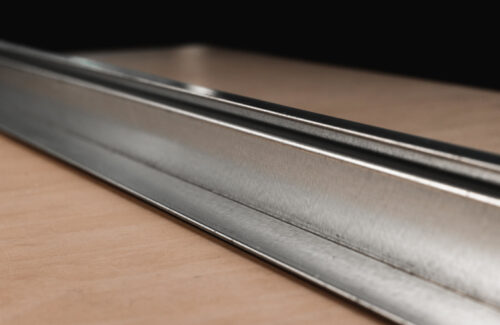

Steel could be the framing material of choice for the solar industry of the future. It’s inherently stronger than aluminum, so it will more easily support the added size and weight of large-format modules. And with new corrosion coating advancements, steel is better able to withstand the increasingly temperamental elements associated with climate change.

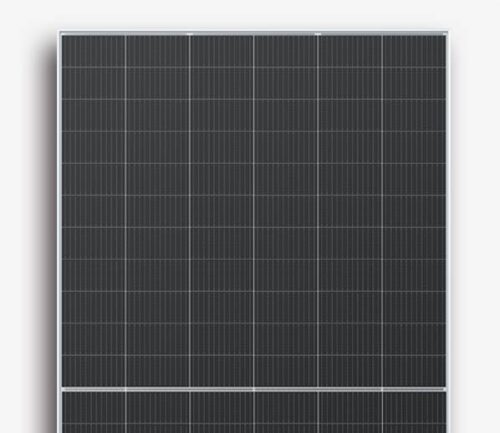

Risen Energy is so far the only module manufacturer that markets a steel-frame option. The Chinese company reinforces its steel frame with a corrosion-resistant zinc-aluminum-magnesium coating to improve strength, cosmetics and lifespan. According to spec sheets, the only difference between a 670-W utility-scale Titan solar panel with a steel frame and one with an aluminum frame is the steel-framed model is 1.5 kg (3.3 lb) heavier.

More than anything, Risen looked at frame alternatives due to aluminum’s large carbon footprint.

“Whatever your belief,” said Luke Sun, president of Risen Energy, in a press release, “environmental pollution and carbon dioxide emissions affect us all. It is simply not good enough for us to proclaim that we are making an impact of reduction of these elements by providing and using solar PV modules, we must do more. Moving to this uniquely constructed module is a step in the right direction.”

Market intelligence firm Boundless Impact Research & Analytics completed an environmental impact report for Origami Solar earlier this year and found that replacing just 10% of the solar industry’s conventional aluminum frames with steel frames would result in a greenhouse gas emission reduction of approximately 30 megatonnes between 2022 and 2030. This is equivalent to the emissions from eight coal-fired power plants for an entire year.

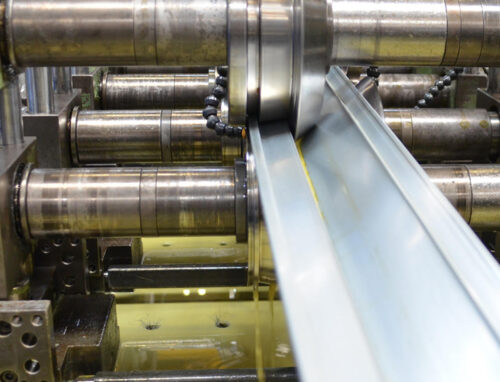

Origami Solar has already built over 4 km of frames to show steel’s similarity to aluminum and begin third-party testing. Steel suppliers have been secured; Origami just now needs module companies to sign on. Patterson said many are interested, especially since Origami’s manufacturing process can provide domestically produced steel frames that are cost-competitive with aluminum imports from China.

“Our goal is to drive adoption of frames and work with the module companies and then the racking and tracking companies to figure out how we can improve the installation costs so we drive solar in the right direction so it can scale to what the world needs. We’ve got to start getting off of that Chinese supply chain,” he said.

“Solar panel frames made of plastic have many advantages that differentiate them from existing frames, such as ease of installation, and therefore have great market potential,” said Steven Kim, leader of the engineering materials division at LG Chem, in a press release.

It is a little miss leading in my opinion. Yes it takes less emissions to produce 1 ton of steel compared to 1 ton of aluminum, but how may frames can be built per ton per aluminum and steel? As stated by others I think we should compare on a per panel.

Steel is graver to comparing cost and emissions solely by weight tells me nothing. The steel frame is heavier as stated in the article. What is the cost and emissions on a frame alone basis?

In the article, it says: “it takes 13.5 MWh of thermal power to produce one tonne of aluminum (equivalent to 11.2 tonnes of CO2), while it only takes 4.5 MWh to make one tonne of steel (1.8 tonnes of CO2).”

Kelly. you need to check your math on your MWh to CO2 conversions. Your numbers are inconsistent. Also for an apples to apples comparison you need energy per frame, including required coating for steel and differing fabrication energy costs. Energy per ton of metal is pretty useless. Lastly, you need to factor in the near universal recycling of aluminum and the vast energy savings achieved when this is done. On more point of fact. You say steel is inherently stronger than aluminum. Since all other measurements in your article are by weight, this is false. Aluminum is far stronger than steel by weight. That is why they don’t make steel airplanes.

Origami is spot on about the future of steel framing. Furthermore, Steel prodcution itself is going green, “green steel” which will further reduce, if not completely reduce CO2 emissions. If I was Origami I would be talking with QCELLS. Could very well be a perfect fit and a low carbon fottprint made in the USA.

Well it makes more sense finacialy to use steel framing instead of aluminum.