Although American solar panel manufacturing is growing and many global brands have set up in the country, the domestic demand far outweighs supply. This often leads to mismatched or unfulfilled orders to needy installers. To ensure contracts are met, some installers might choose to source their own panels and use an original equipment manufacturer (OEM) for smaller orders of custom product.

There are a few U.S. panel manufacturing plants that also offer space as OEMs, and a number of players take advantage — whether it’s a foreign company wanting to deliver a batch of Made-in-USA product or a small domestic outfit with a unique need.

CertainTeed Solar has a network of installation partners that have become accustomed to its high-quality roofing products and want the same in the solar department. Lumos Solar makes beautiful architecture projects with integrated solar that not just anyone can supply. And Next Energy Alliance is a Utah installer and distributor that wants a consistent supply of solar panels. These three companies aren’t trying to be panel manufacturing powerhouses but are supplying niche markets and a steady stream of customers through OEMs.

Veteran manufacturer — CertainTeed Solar

CertainTeed has been an American building mega-company for over 115 years. Primarily known for its roofing products, the company made the logical step to enter the solar market 10 years ago. Not only does CertainTeed, a Saint-Gobain company, produce solar shingles installed alongside traditional roofing shingles and tiles, the company also offers 60- and 72-cell panels installed through its “Master Solar Installer” dealers.

Instead of linking with an established panel manufacturer for its installation partners, CertainTeed produces its own modules through an OEM in California. Chris Fisher, solar product manager for CertainTeed, said this decision was made to have better control over the characteristics, performance, quality and reliability of the products the company sells.

“Having been in the solar industry for more than 10 years, we’ve seen a number of very large solar panel manufacturers come and go as they grew too fast, traded profit for market share or couldn’t create a sustainable compelling product. So, bigger is not always better,” Fisher said.

CertainTeed is capable of producing more than 100 MW of panels in California. The company uses the California OEM to make its Apollo II and Apollo Tile II building-applied PV options and its 60- and 72-cell Solstice panels.

Maybe because CertainTeed is involved with other aspects of the roof, bringing solar products in-house was an obvious choice.

“We fundamentally believe that for the end customer, having a unified, single-source warranty for both the panels and the balance of systems is a much better value than having multiple warranties from disparate component manufacturers,” Fisher said.

Fisher said that although having Made-in-USA panels is an important selling point for CertainTeed, manufacturing domestically reflects the company’s commitment to the United States.

“We’ve been in business in the United States for 115 years,” he said. “With more than 60 facilities in North America and more than 6,000 employees in the United States, we’ve got deep roots in this country, and we want to support it to the greatest extent possible.”

Architectural solar designer — Lumos Solar

Colorado-based Lumos Solar started in 2006 doing both solar product development and installation, but founder and CEO Scott Franklin said the installation side was difficult to differentiate in the race to the lowest price. So, the company switched gears in 2014 and now focuses 100% on product development.

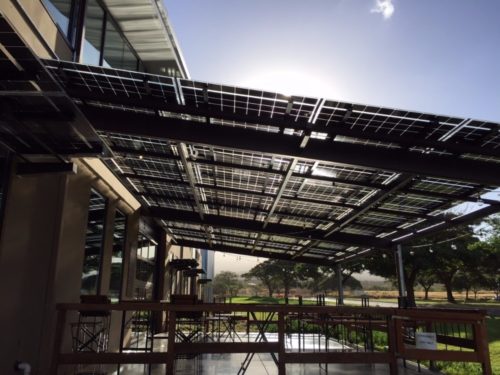

“We’re building solar products that enhance the environment. Most commercial projects are on flat roofs that no one can see. Our products are the entryways — canopies or shade structures that people can live with every day,” he said. “Lumos is changing the perception of solar from an unwanted electrical appliance to a statement.”

“We’re building solar products that enhance the environment. Most commercial projects are on flat roofs that no one can see. Our products are the entryways — canopies or shade structures that people can live with every day,” he said. “Lumos is changing the perception of solar from an unwanted electrical appliance to a statement.”

Lumos is a “solar architectural firm,” working primarily with building and site designers to get its solar products — solar awnings, canopies, pergolas and facades — included in final designs. The company has contracted a California OEM to make Lumos’s proprietary solar panels.

“There is no solution that can do the same thing. We’re not making commodity modules that you can get from anyone,” Franklin said. “Everything is holistically designed from the ground up.”

Lumos produces both mono- and bifacial modules out of California. The LSX is a 60-cell frameless module with a clear backsheet. GSX is a bifacial glass-glass module in a traditional 72- or 60-cell module footprint, but fewer cells can be used to increase module transparency between cell rows. Since each project is so custom, Franklin said the company manufactures panels in “the megawatt range” annually.

“There are a lot of opportunities for improvement in architectural solutions,” Franklin said. “We take a total system approach to design and manufacture our products. Solar panel manufacturers make panels, racking manufacturers make racking, electrical makes BOS — no one is thinking about how the whole project goes together. Our solution solves a lot of those issues — panels, integration, aesthetics.”

“There are a lot of opportunities for improvement in architectural solutions,” Franklin said. “We take a total system approach to design and manufacture our products. Solar panel manufacturers make panels, racking manufacturers make racking, electrical makes BOS — no one is thinking about how the whole project goes together. Our solution solves a lot of those issues — panels, integration, aesthetics.”

Both the LSX and GSX modules have concealed conductors and junction boxes, a “trademark feature” of Lumos Solar.

“We’re focused on overhead solar, like awnings and canopies, where your interaction with it is from below,” Franklin said. “We’ve focused on making that as aesthetic as possible.”

Franklin said Lumos Solar has worked with sourcing modules from China and elsewhere, but bringing that manufacturing control to the United States allows the company to focus on quality.

“We’re committed to Made-in-America for our own beliefs and business practices,” he said. “Everything we make is made in the United States. The only thing coming from overseas are the solar cells and glass. Beyond that, we make it all here.”

Distribution newcomer — Next Energy Alliance

Next Energy Alliance is very new to module manufacturing. The distributor/installer in Utah got involved in manufacturing after founder Doug Hewitt was struggling to secure panel orders from bigger names.

“I was buying direct and it just became a joke of trying to make sure I had inventory,” he said. “One month I was buying Trinas at 330-W and they were guaranteeing me that I could get them. Then when it came to order, they’d only have 295-W.”

The demand for panels was so large that companies would guarantee something, and it’d be gone the next day, Hewitt said. So that’s when he started looking at getting bulk supply from Asian companies. Eventually that led to working through a Southern California OEM for NEA-branded panels.

“I was getting stuff overseas and decided really quickly that navigating tariffs was difficult. So I talked to three different manufacturers in the United States and decided to have someone make my panels,” he said. “I’m just pulling a ‘Nike model.’ They decided, ‘We’re not going to have our own factories everywhere. We’re just going to outsource it.'”

Hewitt also mentions that almost all tier 1 companies adopt this outsourcing process, and many Southeast Asian OEMs have reached out to Next Energy Alliance to make NEA panels on their manufacturing lines alongside other tier 1 brands. When customers ask for tier 1 panels, they’re requesting an industry marketing term that does not reflect panel reliability or performance. Next Energy Alliance panels are UL certified and have received high marks on performance scorecards.

Hewitt also mentions that almost all tier 1 companies adopt this outsourcing process, and many Southeast Asian OEMs have reached out to Next Energy Alliance to make NEA panels on their manufacturing lines alongside other tier 1 brands. When customers ask for tier 1 panels, they’re requesting an industry marketing term that does not reflect panel reliability or performance. Next Energy Alliance panels are UL certified and have received high marks on performance scorecards.

Hewitt envisions Next Energy Alliance as a network of solar companies, connecting sales with installers and providing guaranteed product. For now, the company is making all-black 60- and 72-cell NEA modules through the California OEM. Hewitt said he only offers all-black modules because he wouldn’t put a white backsheet on his own home, and people are worried about aesthetics. Next Energy Alliance either sold or personally installed almost 7 MW of NEA modules last year.

Hewitt said he tries to have at least five containers of modules in stock in the warehouse at all times. NEA and the OEM can scale to 20 containers a month, but the company isn’t quite to that level yet. Next Energy Alliance was recently approved with Dividend, Loanpal and Sunlight Financial, so wheels are in motion.

Today’s focus is just making solar installers’ lives easier.

“The plan is to continue to build that distribution and relationships,” Hewitt said. “We’re not just a manufacturer — we’ve done it all. We’ve done installs. We know the pain and heartaches for contractors.”

Yeah, I see ‘their’ point on panel reliability and output, but I am skeptical that “panel uniformity” is the reason to go OEM manufacturing. There are many talking about bifacial solar PV panels now and I have seen some “reports” from China, “pre-Conv-19” that say a manufacturing run of bifacial can come in at $0.28/watt. I’ve seen “reports” saying the large output around 400 watts mono-facial PERC can be bought in manufacturing quantities at $0.43/watt including tariffs. So, it is very important that entities like solar power world write about what’s being done on the World manufacturing stage. For instance on the CertainTeed solar PV panels mentioned, I found a specification sheet declaring about 15% efficiency for the panel. I can get Panasonic HIT panels in the 330 watt range for around $1.25/watt retail. Smaller panel foot print package, around 19.5% efficiency and better low light harvest performance over other panel “chemistries”. The HIT technology is right at 20 years old and was the intellectual property of Sanyo, until Sanyo went bankrupt due to cheap Chinese panels. Now Panasonic has picked up this intellectual property and continues on with their own line of HIT panels.

Apparently, Tier 1 panels are not ‘necessarily’ the “best” panel for the job, I believe it can still be used t see just how ‘bankable’ and therefore how many have been installed. With automated manufacturing being used all along the supply train, one can be fairly confident that ingot to solar PV cell, to manufactured panel is more consistent today than 20 years ago. Lets face it, stuff installed in the late 1990’s and early 2000’s will not be “proven by their long term use”, this data will not be available for another 5 to 15 years. Then one needs to take a look at these early manufacturing line panels to see what the actual expected service life of a solar PV panel (IS). Could it be on “average”, 30 years, 40 years, 50 years? Even with older panels degrading with an average of 1% a year, if one has an old system on their roof, would replacement of electric appliances with energy star units over the years make up for the solar cell degradation over decades? The industry as a whole is at a “price point” that one could replace their panels every 10 years for the latest/greatest technology, just like folks now-a-days replace old cars with new ones that offer the latest/greatest technologies.