Fronius

The National Electrical Code (NEC) is a frequently changing set of rules published by the National Fire Protection Association (NFPA), also referred to as NFPA 70. The latest edition was published in August 2022, but four jurisdictions have already adopted it with 13 others in the process to adopt.

The solar industry should pay particular attention to changes in one part of the 2023 code — section 690.12. This section regarding rapid shutdown requirements has significantly changed over the past few NEC editions. The 2023 version included some minor but important changes as well.

2023 rapid shutdown changes

Compared to the 2020 code cycle, the 2023 changes in this section were minor. The focus was on clarifications and editorial changes to place rapid shutdown requirements in one location.

- A second exception was added to clarify that parking shade structures, carports, solar trellises and similar structures are not required to comply with 690.12 since firefighters typically do not perform rooftop operations on these types of buildings.

- An exception was added to allow PV system circuits originating from arrays not attached to buildings that are terminated on the exterior of buildings. These PV system circuits installed in accordance with 230.6 are not considered controlled conductors for the purpose of 690.12.

- Option (3) for inside of the array boundary was deleted since these systems must be evaluated according to UL 3741.

- Rapid shutdown marking requirements from 690.56(C) were moved to 690.12(D), including minor changes in the requirements for the marking.

Even though module-level options are allowed in the code, a number of factors make it clear that opting to satisfy UL 3741 instead is the way to go in the future.

- Avoid high numbers of additional connection points and mismatching PV connectors.

- Eliminate interference of rapid shutdown devices and arc fault detection.

- Eliminate the reliability concerns due to the rapidly increasing number of electronic components in an extremely harsh environment.

- A method of better wire management and wire protection that complies with UL 3741 to reduces the chance of faults and the likelihood of thermal events.

Issues with module-level rapid shutdown

Solar power electronics, such as inverters and combiner boxes, are well-established technologies that have been installed for over two decades, whereas module-level power electronics (MLPE) are still relatively young in the industry. MLPE require significantly more components and connection points within the PV system, which can create problems as all these individual components must be properly integrated to function correctly. Some examples of these problems would be the interference caused by MLPE and the ability of arc-fault detection to properly detect arcs, as well as installation errors such as mismatched or not fully mated connectors. As the number of components and connection points increase, these types of complications are more likely to occur.

Electrical noise created by additional components could be interpreted as an arc-fault and cause false or unwanted tripping. On the other hand, MLPE could also prevent arc-fault detection by filtering, masking or attenuating real arc events.

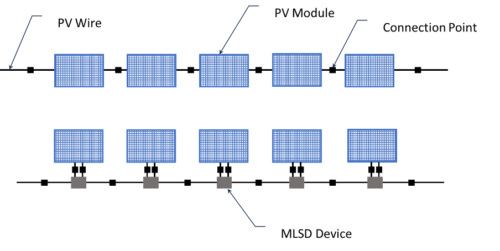

Figure 1 illustrates an example of a string with five modules and how the number of connection points are affected with and without module-level shutdown devices (MLSD).

Even a string with only five modules, which is short for a string inverter, would have more than twice (2.6-times) as many connection points compared to a module-integrated solution or a PV system utilizing UL 3741, the Standard for Safety PV Hazard Control. UL 3741 provides an option for PV hazard control without the use of MLPE.

Figure 1: Example of connection points with (16) and without MLSD (6)

Figure 2 illustrates the number of connection points in a PV system as a function of the number of modules with and without MLSD. The dramatic increase in connection points with MLSD is alarming. Improper installation practices, such as missing dust caps, leave PV connectors exposed and susceptible to dust and oxidization when the installation is not completed promptly.

Figure 2: Number of connection points for different string lengths with and without MLSD

Figure 3: Failure of PV connectors

Each additional electronic component installed in the harsh environment of a rooftop increases the risk of a failure.

With the assumption based on Warranty Week research that the constant annual failure rate of one component is 0.075% (750 parts-per-million (ppm)) and 4,000 components are used in one or multiple PV systems, three failures per year or 45-60 failures in a 15-20-year PV system lifetime can be expected. Table 1 lists examples of failure rates for different system sizes and multiple systems.

Even if the failure of one MLSD does not affect the entire string, it would be labor-intensive to remove the existing modules and the faulted MLSD and replace it. This could also create new problems caused by disconnecting, testing and reconnecting each system component during the troubleshooting process or the availability of compatible components 10 years from now.

Figure 4: Constant annual failure rate of 750 ppm

Table 1: Examples of failure rates

The assumption of a constant annual failure rate is a simplification and neglects the early failures of components. When these are factored in, it increases the number of failures significantly.

History of section 690.12

It is important to know that section 690.12 is intended to reduce the shock hazard originating from PV system circuits on buildings for firefighters. This does not include installers during installation and maintenance!

Section 690.12 was introduced for the first time in the 2014 edition and was modified multiple times. The 2014 edition had only requirements for outside of the array boundary, but this term was not introduced in this edition.

In the 2017 edition, additional requirements for inside of the array boundary were introduced. This edition included three methods to comply with the inside-of-the-array-boundary requirements, however the only method available at the time was the use of MLPE. Both requirements inside and outside of the array boundary must be fulfilled.

The direct linkage to UL 3741, Standard for Safety Photovoltaic Hazard Control, was added in the 2020 edition. UL 3741 was published on December 8, 2020, and provides methods to analyze and reduce the hazard for firefighters operating inside of the array boundary.

UL 3741 provides two methods, or a combination of both, to reduce the hazard for firefighters. One method is to limit voltages inside of the array boundary to a level that would not create a hazardous current flow through the firefighter’s body. The other is to reduce the risk of a fault due to firefighter interaction and/or to reduce the risk of any secondary faults causing current flow through the firefighter’s body.

Additionally, UL 3741 makes PV arrays safer due to improved and detailed installation instructions, defined materials and methods and performed risk analyses. These methods and reducing the number of components and connection points contribute to a safer and more reliable system.

More points of connection means more possible points of failure, and electronic circuits don’t like heat. Rooftops are subjected to temps that exceed 160F.

Excellent article – system simplicity is key (less connections is inherently more safe), even more for the solution required by First Responders exposed to the risks that PV systems can provide. We strongly believe that until PV systems are engineered, inspected and maintained to be failsafe or a method for early fault detection for all PV systems is mandated and implemented at initial installation phase as a priority, then the application of a temporary light blocking coating to the panels which will safely de-energise the entire system is the best available option to First Responders. We are seeing global Firefighters increasingly turning to this solution as they seek a simple, safe and effective solution in their toolkit to Make Safe and Isolate the Risk for incidents where solar PV systems are involved.

This enables a form of stasis from which PV system faults can be safely identified and resolved by competent personnel, or if the source of ignition is not the solar PV system then the PV system risks are mitigated for First Responder safety as they carry out their tasks. What I do find strange is that UL do not consider including a solution that addresses the energy generation at source for First Responders: stop the source, protect lives and assets safely.

Simplicity is key. Adding things like disconnection relays and multiple extra connections at each panel is a TERRIBLE solution seemingly driven by a couple of companies that manufacture such solutions. In my professional engineering opinion – MLPE has made solar much less safe by significantly increasing the risk and in practice – the number of fires that first responders have to respond to in the first place. In my fire investigation experience traveling the country to investigate solar related fires; MLPE devices and PV connectors are the main causes of solar system fires.