Dr. Ahmed El-Rasheed

More new solar was installed last year than any other electricity source. All those systems will require periodic maintenance to ensure they’re performing as promised. Solar energy technicians use their field experience and the latest tools to keep projects on track.

A solar technician’s duties include reading blueprints and schematics; testing and troubleshooting inverters and data acquisition systems (DAS), IV curve tracing, insulation resistance testing, earth ground testing, infrared thermal imaging, as well as many other additional tasks. Solar energy technicians must also learn, and stay current with, local, state and federal codes for solar PV installations, as well as interconnection regulations.

When considering how important solar power is becoming for American energy consumption, it’s important to consider the varying activities a solar technician is expected to perform on any given day and how the electrical testing community can better support these duties.

“A typical day for me can vary depending on several factors,” said Corey Brown, senior technician and district manager – NJ at Tri-Force Energy. “A lot depends on site access hours, weather conditions and solar access window — which is important for IV curve tracing. My onsite start time and amount of travel driving may differ each day as well,” he said.

There are a variety of tasks that may need to be completed throughout a technician’s day, including troubleshooting communications or equipment, performing preventative maintenance on solar equipment, quality control and commissioning of newly built solar systems. Ron Celentano, a solar PV consult for nearly 30 years with Celentano Energy Services said, “It is important to conduct many of these tests during the commissioning phase of a new project to establish a baseline. These test results can be compared against results from tests conducted in the future.”

“Ensuring that we are fully equipped with training, the appropriate personal protective equipment (PPE) and reliable high quality electrical testing equipment is key to our success in the field. Our clients rely on us to provide them with efficient services to ensure that their investment in solar PV assets is well protected. Keeping solar PV systems alive and performing is what we do day-to-day,” said Tri-Force’s Brown.

Having the appropriate equipment on a solar jobsite is extremely important to get the job done correctly. These tools and resources help technicians safely, effectively and efficiently install, maintain, commission and troubleshoot solar systems of all sizes. “In addition to conducting tests and taking measurements using these instruments, it is essential that the technician properly interprets the results to correctly diagnose problems, which is why periodic O&M training is very important,” said Celentano.

Getting ready to test solar PV.

Technicians need accurate and easy-to-use tools when working on PV systems. There are a variety of tools on the market that not only help technicians do their job and meet their needs, but also provide system owners and operators with the information they require to maintain their investment.

“Each day isn’t the same, but certain days may be designated for specific tasks and having the right tools to perform those tasks is important to how my day will go,” said Brown.

Servicing a solar PV system

Since PV systems seem to be becoming increasingly popular in the electrical industry, arrays are being installed in a wide variety of locations. Because of this, electrical contractors need tools for testing and maintaining systems in these locations.

Commercial PV arrays in the United States are generally designed and installed with voltages up to 1,000 VDC on rooftop arrays and 1,500 VDC on ground-mounted arrays. Additionally, many systems are interconnected with the utility at distribution and transmission voltage levels.

To meet the needs of technicians, companies that manufacture electronic test equipment and measuring instruments for electrical power applications have several different tools that make a technician’s job easier. These tools are used in the field at all stages of installation, operations and maintenance. Some of these tools include a digital AC/DC clamp meter, an irradiance sensor, a temperature sensor or infrared thermometer, an insulation resistance tester, an IV curve tracer meter and a thermal camera.

“When I’m onsite, I often conduct a simple system performance test using an irradiance meter and a temperature sensor, which are used to normalize DC power generation and voltage relative to the solar PV module specifications at standard testing conditions (STC). Applying those normalized values to the total PV array capacity and incorporating assumed industry standard derating and adjustment factors, the estimated AC power generation can be calculated and compared to the power generation displayed by the inverter.”

High voltage handheld insulation and continuity tester being used for testing in PV combiner box.

On the day of a standard service visit, the technician arrives at the site first thing and makes sure everything is ready to go.

“I first take a look at the plans regarding the equipment being installed. Then I review all equipment manuals to ensure that the equipment is in line with the specified requirements,” said Brown. “Once this is complete, I follow the pre-defined scope of work and do my best to ensure that the system is safe, fully operational, communicating and performing as expected.”

Upon completion of the service visit, technicians need to verify the performance of the system, including the PV array. Doing this requires multiple tests to be run and corresponding data points to be collected. Using a digital clamp meter and an irradiance sensor allows technicians to measure the important values and record the data for verification.

Maintaining a system

The majority of systems need to be maintained at least one time per year for the typical C&I system, but in the utility-scale space, there may be quarterly or semi-annual visits. During a maintenance visit, technicians conduct thorough inspections and follow the recommended procedures outlined in the technical manuals that came with the system. Sometimes when visiting a site for maintenance, an issue will pop up and technicians will troubleshoot and repair any issues identified during the maintenance process.

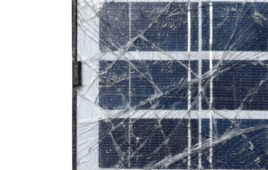

Technicians need to rely on the same tools they used for installation to troubleshoot and maintain a solar system. For example, a thermal camera helps a technician identify potential problems within the array itself, or inside any of the electrical equipment where poor connections may be causing a problem. An insulation resistance tester helps to identify when hazardous ground faults are present due to compromised wires.

Testing for cable fault location in solar PV.

Troubleshooting and repair

There are times when technicians are called out to a site to troubleshoot an issue or to repair equipment that is not working properly. Prior to going out to a site, the technician will review plans and notes regarding the issue at hand. They also take the time to ensure that they have reviewed the equipment manual and they have contacted the monitoring and manufacturing team to see if there are any ongoing cases related to the equipment or site.

“Having site knowledge prior to showing up to it is almost as important as having the right tools with you to do the job. Sometimes things don’t go as planned and it is important to not only have good site knowledge, but also application information. Knowing what your equipment does and how it can help to troubleshoot something that maybe didn’t go as planned can be critical when you are working in some of the situations we work in,” said Brown.

Challenges of the job

Challenges like inverter underperformance and communications can creep up at any time during a job, but if technicians are equipped with the right information and equipment, a lot can be remedied with great ease.

“Having technology offered to technicians either in an all-in-one tester/tool or a bundle is really important,” said Brown. “No one wants to carry around a bunch of bulky, heavy equipment. Especially if we are climbing 30’+ internal building ladders or are in tight spaces inside large central inverters. The more functionality one tool offers, the better.”

What manufacturers can do to help

Companies that manufacture electrical test equipment strive to make a solar technician’s job easier. They know that it is important for a technician to have the tools and resources at their fingertips to help them safely and effectively install, commission and maintain PV arrays of all sizes.

Having the correct tools to perform their job makes a huge difference to the technician. Easy-to-use, compact handheld tools are essential when working on PV systems. What’s even more appealing is when these tools are offered in a bundle or kit.

Companies like Megger understand what it is that technicians want and need and have taken to offering solar technicians solar test kits. These simple kits include a digital clamp meter that measures current in a wire; an irradiance sensor that allows users to quickly measure the irradiance or intensity of the sunlight striking the array; an insulation tester that measures the total resistance between any two points separated by electrical insulation; and a thermal camera that allows the technician to quickly and safely assess the PV modules, junction boxes, combiner boxes and electrical connections for abnormal heat.

By supplying technicians with what they need in a one-stop-shop, grab and go format, companies are offering them a comprehensive and convenient solution to get the job done.

Jobs of the future

The Bureau of Labor and Statistics predicts that the demand for solar installers will grow by 52% between 2020 and 2030. The increase in solar energy use will create a greater demand for installers who must install, maintain and fix systems. There will be no shortage of these jobs as people continue to use solar to power their world.

Tell Us What You Think!