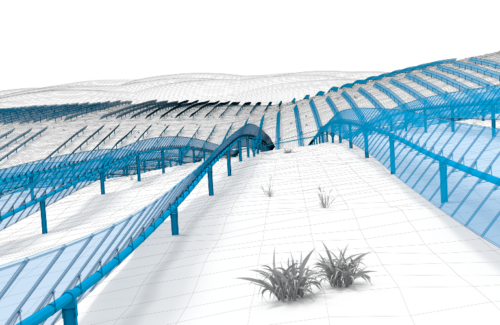

Many single-axis solar tracker manufacturers have developed new iterations of their rotating racking that can be installed on uneven topographies, potentially unlocking large-scale solar development in hillier regions.

Credit: Array Technologies

Historically, the ideal setting for a single-axis solar tracker project has been on flatter land that would require little to no geotechnical grading. No land parcel is perfectly flat, and the value of sites close to fitting that description are growing in both demand and cost.

When developers don’t have to grade land, it can shorten the permitting process, leave native vegetation in place and deter erosion. Skipping grading also means developers can spend less money on site preparation.

“We heard from our customers, and they needed help. What you hear is, ‘We want to invest in a certain kind of land, but it doesn’t make sense a lot of times,’” said Erica Brinker, chief commercial officer and head of ESG at Array Technologies. “Some of the very progressive developers globally, they don’t want to disrupt the topography, they don’t want to change the environment.”

In the last year alone, three of the largest single-axis solar tracker manufacturers unveiled proprietary solutions for deploying these solar projects on uneven land. Array Technologies debuted OmniTrack; Nextracker released the NX Horizon-XTR; and Nevados Engineering developed its All Terrain Tracker.

Each system has different drive mechanisms and row architectures, so their solutions for tackling uneven land differ as well. All systems also promise shorter foundational pile lengths.

Nevados’ All Terrain Tracker has articulating bearings atop foundations that let each panel-bay install at different angles while maintaining rotation. Nextracker’s NX Horizon-XTR has an undulation tolerance of 0.75° between piles and a total slope tolerance of 8.5°.

Array’s DuraTrack single-axis tracker can install on uneven surfaces because it can adjust by 1° from pile to pile. Unlike Nevados and Nextracker, Array’s trackers rotate by using inter-row drive lines, so the hurdles to working on undulating land were adjusting pile heights and increasing the number of motors in a block.

“It’s a mindset shift in the way that you think about the torque tube, because we’re asking the same torque tube to do something different,” Brinker said. “In a motor block, there’s a lot more torque when you’re moving at different angles instead of a straight line. You’re asking for more capability from those parts.”

Single-axis solar tracker deployment will undoubtedly increase in hillier regions in the coming years thanks to this new built-in slope tolerance. Nextracker has already deployed the NX Horizon-XTR in more than 2 GW of projects, and Array’s OmniTrack is hitting the market in 2023.

“Our customers are telling us that this opens a huge opportunity for them,” Brinker said. “They haven’t quantified that for us, but there are many places that were once thought impossible to put solar, especially a utility-scale solar site where you need a large amount of land. They’re telling us there’s incredible opportunity to permit more places, especially with the timing of the IRA bill. So developers and investors feel that we have a long enough runway to actually make that investment.”

This story is part of SPW’s 2023 Trends in Solar. Read all of this year’s trends here.

A great friend and Builder..Burke Denman, who is sadly no longer with us, solved this for DIY folks together nearly twenty years ago, No commercial systems were available for our twisted available land, so he split axels intended for travel trailers. Yup! They come in several sizes.. We couldn’t find sufficient market then. We were using Enphase singles but neither they nor the other supporting equipment AND the local building code for grid attachment made things practical.

I just had installed the latest Enphase All House equipment with software monitoring and control. It is spectacular… Others may be as good,,, I didn’t dig that deep, but watching these equipment share power situations between the grid, the PV and the batteries, all the while operating within the Utility pricing structure….is remarkable…

These inexpensive and really environmentally secure devices come with side load tolerant tapered bearings and the wheel bolt pattern for easy installation to the end supports and rotation devices.

From operations, we did find that unless space-constrained, it was preferable to avoid all the monitoring and maintenance issues by simply adding a limited number of panels offset to provide early and late energy than move arrays.

Considering ALL he cost savings, initial and operational, makes a challenging trade-off.

if space is available.. What are your thoughts?